Flax field in France - Production of flax fibre-based composites

We work to develop high-performance, durable materials to support the evolution toward more responsible industrial practices.

Our ambition: to design, manufacture, and promote solutions that are more durable and environmentally conscious. Step by step, we are integrating these principles into our strategy.

A strategic direction. Eco-responsibility is becoming the core of our innovation. We are gradually integrating eco-design into our developments by rethinking products from the start to limit environmental impact throughout their life cycle: choice of raw materials, manufacturing processes, use, and end of life.

A lever for the future. We are strengthening our expertise in Life Cycle Analysis (LCA), a key methodology for assessing and reducing the environmental impact of products. By training our teams on this strategic tool, we are preparing to optimize design and manufacturing choices to offer increasingly responsible solutions.

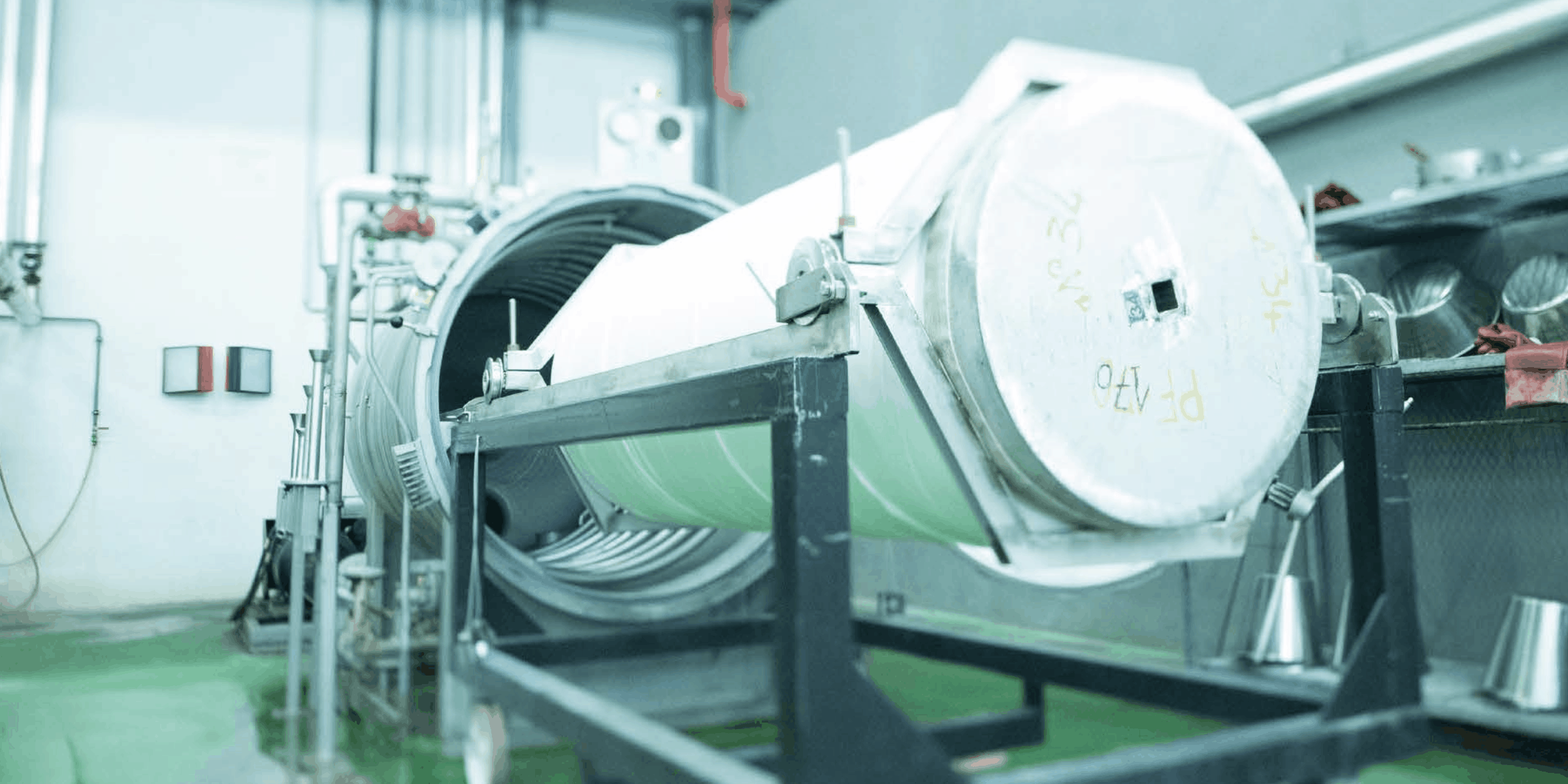

We now recover 23% of weaving water for use in our treatments, reducing our water needs. For better monitoring, separate meters have been installed on our Jiggers and Autoclaves, allowing us to analyze and manage consumption more precisely. Correcting our water discharge reports ensures greater transparency and stricter management of our environmental impact.

Porcher industries recycles fiberglass scraps to reduce waste and preserve resources. At our BGF sites in the USA, production offcuts and selvages are reused as raw materials in E-glass manufacturing. This circular economy approach limits industrial waste and reinforces our commitment to recycling and sustainable development.

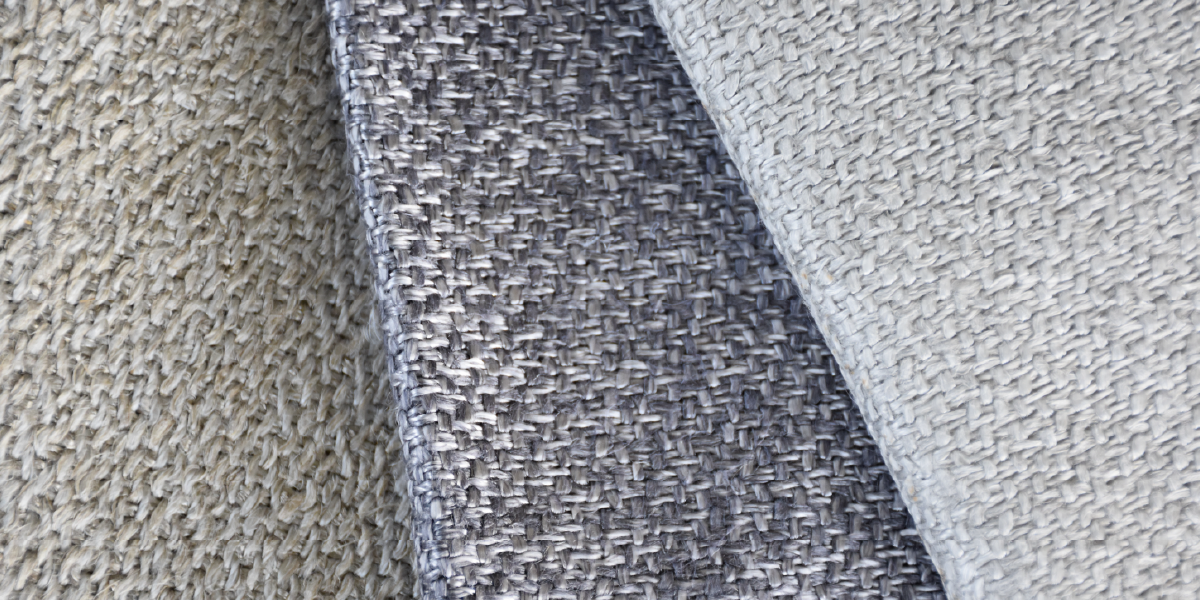

To reduce the carbon footprint of automotive parts, Porcher industries develops thermoplastic solutions reinforced with flax fibers. These bio-reinforcements offer lightness, strength, and aesthetics while helping lower Scope 3 emissions. A sustainable innovation for recyclable, high-performance materials.